Mark Ermatinger, Founder of the Advanced Manufacturing Expo and GM of Industrial Control, decided to test the NEW AI platform, and here are the results in 5 seconds.

Question: Hey Chat GPT, write me a story about how AI is changing the factory floor.

Author: CHAT GPT (https://chat.openai.com/)

Once upon a time, in a bustling town known for its manufacturing prowess, there stood a factory that was about to undergo a remarkable transformation. This factory had been producing goods for decades using traditional methods, but its owners saw an opportunity to embrace the power of AI and revolutionize their operations.

With the decision made, the factory floor buzzed with excitement and anticipation. The workers, accustomed to the repetitive tasks of assembly lines, wondered what changes were in store. The factory management called upon a team of AI experts to introduce cutting-edge technologies into their operations.

The first step was the installation of a network of sensors throughout the factory. These sensors collected vast amounts of data in real-time, monitoring every aspect of the production process. Temperature, pressure, machine performance, and even worker movements were all meticulously captured. The factory floor became a living, breathing network of information.

AI algorithms were then employed to make sense of this torrent of data. The algorithms analyzed patterns, detected anomalies, and learned from historical data. As the AI system gained insights, it started making autonomous decisions to optimize production efficiency.

Robotic arms, guided by AI algorithms, joined the human workforce on the factory floor. These robots had learned to perform complex tasks, such as intricate product assembly and quality control inspections. Collaborative robots, or cobots, worked alongside human operators, effortlessly taking on repetitive and physically demanding tasks. The workers found themselves freed from monotonous work, allowing them to focus on more creative and critical aspects of the production process.

The AI system also introduced predictive maintenance to the factory. By analyzing data from equipment sensors, it accurately predicted maintenance needs, avoiding unexpected breakdowns. The factory floor became a harmonious symphony of machines working at their peak efficiency, reducing downtime and increasing productivity.

Quality control underwent a revolution as well. AI-powered computer vision systems inspected products with incredible precision, identifying even the tiniest flaws that might escape human eyes. Defective products were flagged in real-time, ensuring that only the highest-quality goods made their way to customers.

As days turned into weeks and weeks into months, the factory transformed into a model of efficiency and productivity. Production output soared, costs plummeted, and customer satisfaction reached new heights. The workers, once unsure about the changes, became champions of the AI-driven revolution. They had embraced the new technologies, working side by side with AI systems to achieve greater success.

The town marveled at the factory's transformation and recognized the impact it had on the local economy. Other factories followed suit, incorporating AI into their own operations, and the town became a hub of advanced manufacturing. The community thrived, and workers acquired new skills to adapt to the evolving industry.

The story of the factory spread far and wide, inspiring manufacturers across the world to embark on their own AI-driven journeys. The power of AI and automation had forever changed the factory floor, ushering in an era of intelligent manufacturing that maximized efficiency, quality, and human potential.

And so, the factory that once hummed with the sound of traditional manufacturing now hummed with the harmonious blend of human ingenuity and artificial intelligence, shaping the future of industry in remarkable ways.

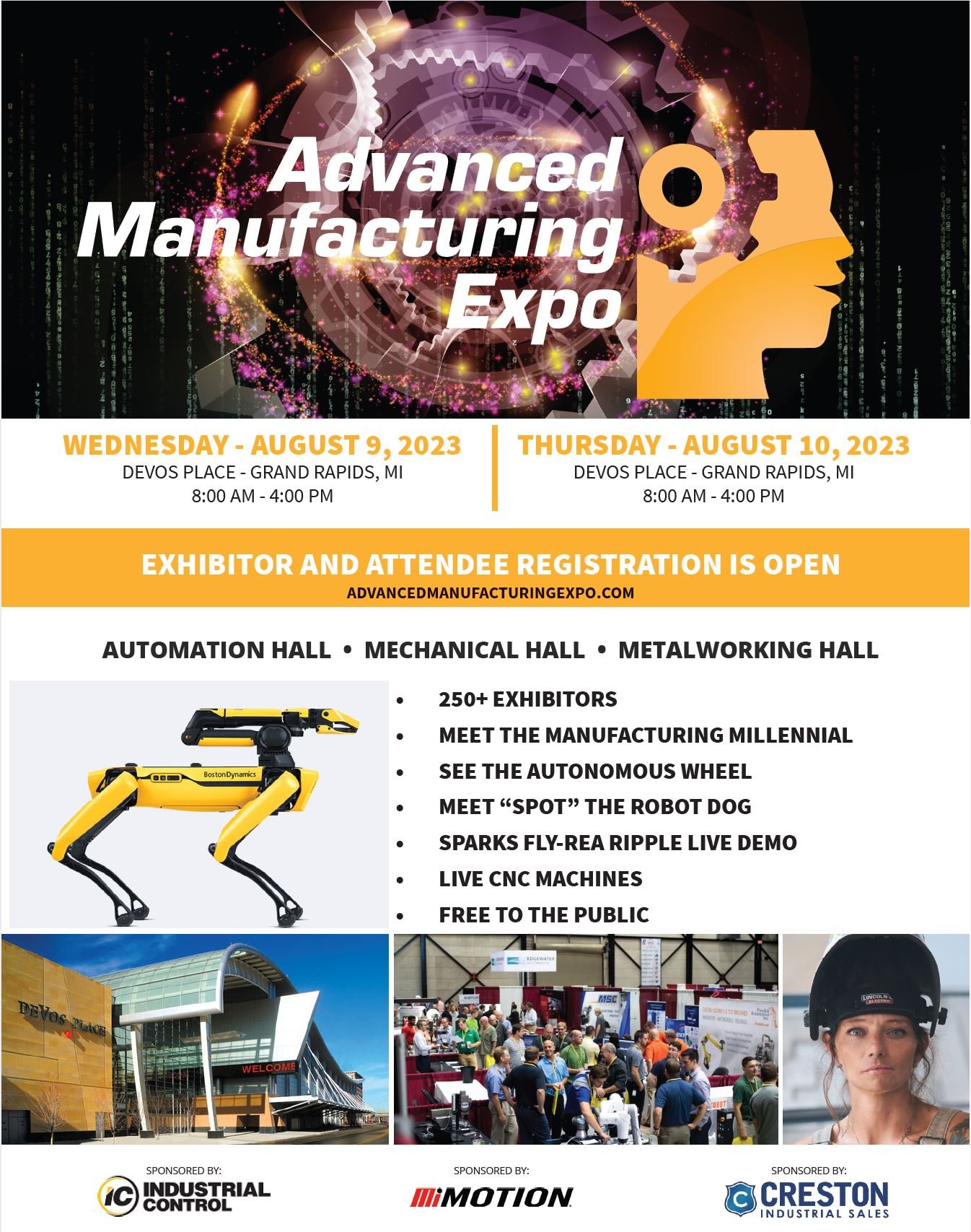

Click here to read the full story from the Advanced Manufacturing Expo 2023 program.